Pre-thickening systems for Pusher centrifuges

Ensure consistent process conditions with Ferrum pre-thickening systems for pusher centrifuge applications.

Pre-thickening - an important process step

As a continuously operating machine, the pusher centrifuge requires process conditions and solids concentrations as constant as possible to ensure optimum operation and consistent product quality.

For process and plant-related reasons, the necessary feed conditions are often not achieved. As a solution for this problem, Ferrum offers various pre-thickening systems and dosing devices.

Depending on requirements, Ferrum supplies the design, production and automation of the related system.

Integrated thickener – a Ferrum innovation

The integrated thickener for pusher centrifuges was developed by Ferrum. Depending on the application, separate, external pre-thickening is no longer required. Fluctuating feed concentrations are compensated, the cake formation is improved and the product accelerated more gently. The integrated thickener is today our standard for certain applications.

Static thickener

The static thickener is used if the sedimentation behaviour of the solids and the space available permit. The thickened suspension can be supplied to several centrifuges at the same time via the Ferrum dosing unit.

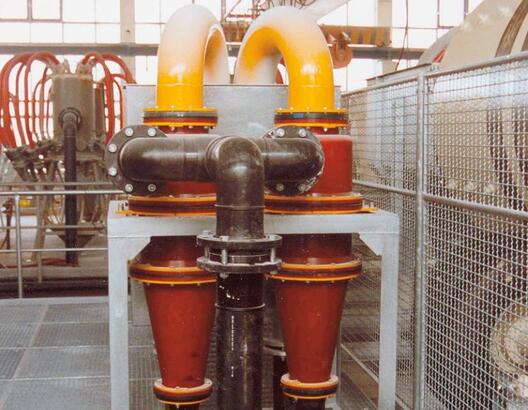

Hydrocyclone

Solids and liquid are separated by centrifugal acceleration. The thickened suspension at the solids outlet is fed to the centrifuge. The use of hydrocyclones requires a solid with a higher density than that of the mother liquor as with the static thickener.

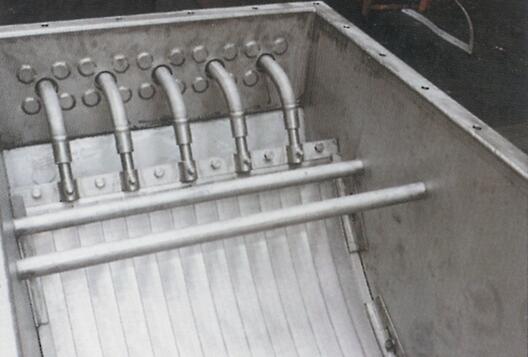

Curved sieve

The suspension is distributed onto the curved sieve surface under pressure. During this process a part of the liquid is separated via the sieve slots. The thickened suspension is collected at the end of the sieve and fed to the centrifuge.

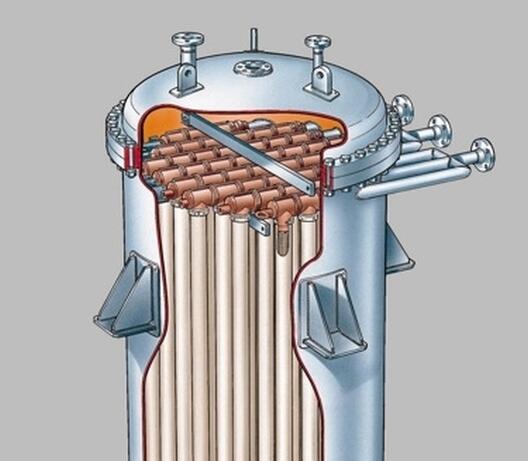

Cartridge filter

The pre-thickening is achieved by the pressure difference (ususally an over-pressure at the cartridge filters which are in a closed container. Cartridge filters operate discontinuously. To achieve a continuous process, the thickened suspension is fed to a collection tank before entereing the centrifuge.

Brochures

Download matching brochures for the product as PDF here.

Your contact person

Find the right contact person for your needs at Ferrum, our agencies and locations.

We look forward to hearing from you.