Latest scraper unit generation - Centrifuge upgrade from Ferrum

26. Sep 2011

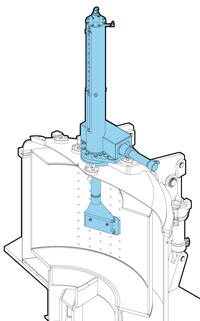

New scraper units developed by Ferrum - easy and fast modification

The scraper unit developed by Ferrum has been used for new machines for several years and has been proven in numerous applications. With the new design you benefit from considerable advantages.

Our innovation - Your benefit

- Parts made of corrosion-resistant materials

- Fewer wear parts due to simpler design

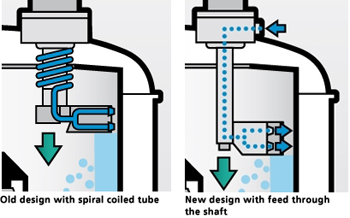

- Simplified and optimised hydraulic system

- Internal nitrogen feed to the residual heel removal system, the external spiral coiled tube can be eliminated

- cGMP design

Lower maintenance costs and shorter downtimes

The simplified and even more reliable design with components made of corrosion-resistant materials, increases the effective operating time and reduces downtime for revisions and repairs.

Higher efficiency

The new cGMP design minimises product deposits. This allows a significantly more efficient and faster cleaning of the scraper unit in the process area reducing time for batch and product change.

Simple and fast up-grade

- Mechanical installation within one day

- Complete modification kit: scraper unit, hydraulic unit, valve block

- No modifications of the cover or housing required

- Customised adaption of the control system

Nitrogen feed through the scraper shaft

Modification possible with the following centrifuge types

VBC, DSZ, PUR BN, PUR DIN

Contact person at Ferrum:

Mr. Dirk Keser

E-Mail

T +41 62 889 1390

Download this newsletter here.

For further Information regarding “Ferrum Centrifuge Technology” please click here.