Double throughput with the D-ACT® pusher centrifuges

26. Jan 2018

The D-ACT® pusher centrifuge is a special design of the standard pusher centrifuge, developed and patented by Ferrum.

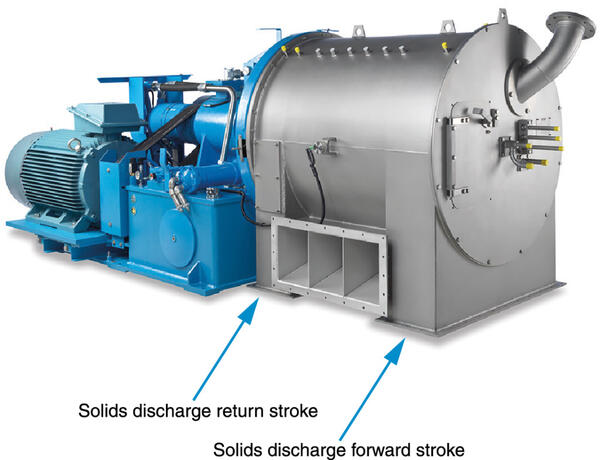

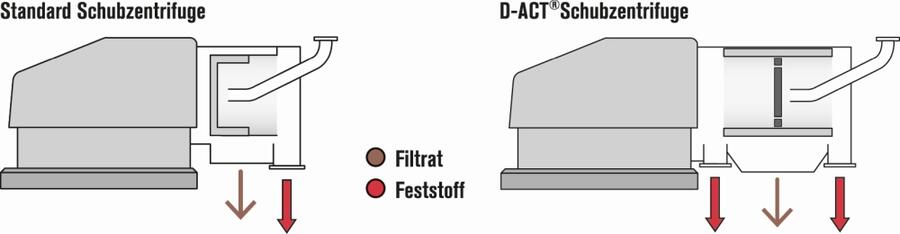

The D-ACT® pusher centrifuge is a special design of the standard pusher centrifuge, developed and patented by Ferrum. The operating principle is basically comparable but the suspension is fed in the axial centre of the basket. The pusher plate with kidney-shaped outlet ports enables the suspension to build a cake on both sides of the pusher plate. With the forward stroke, the cake is transported to the front side, with the return stroke to the back side of the pusher plate. Therefore, solids are discharged with every pusher movement.

This operating principle has been known for several years and a number of machines are in industrial operation. During the recent revision of the machine, different improvements/optimisations have been integrated.

Under optimal conditions, the D-ACT® pusher centrifuge type PD-80 can achieve the same throughput as a conventional pusher centrifuge type P-100. The specific energy consumption is, based on the more efficient exploitation of the pusher movement, approx. 20% lower and the machine requires a smaller floor space. With this, the D-ACT® pusher centrifuge offers a cost-efficient solution for both acquisition and operation where the requirements for residual moisture and/or washing effect are not crucial.

The D-ACT® program is, besides the PD-80, complemented with the PD-60 and the PD-100. Therefore, throughput rates of up to 120 t/h per centrifuge, e.g. for KCl, can be achieved.

More technical information is shown on the data sheet. To learn more or to request a quotation, please contact the Area Sales Manager responsible for your region. You are welcome to return the questionnaire filled in with the process data of your specific application. Take advantage of the creative solutions from Ferrum.

We look forward to hearing from you soon.

For further information regarding "Ferrum Centrifuge Technology" please click here.