CIP and SIP systems for Ferrum centrifuges

CIP and SIP systems from Ferrum to avoid cross-contamination at product or batch change.

Clean

CIP system

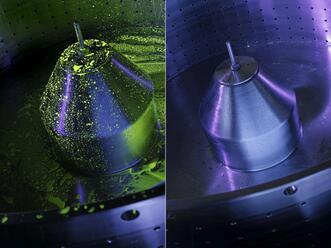

For cleaning the centrifuge process area, a CIP system (Cleaning In Place) can be integrated in all our vertical centrifuges. This system is used during a product or batch change to eliminate the risk of cross-contamination. The CIP nozzles, the feed and wash system as well as the residual heel removal outside the basket clean the process area.

SIP system

After the CIP cleaning, SIP cleaning (Sterilisation In Place) can be undertaken. To eliminate microorganisms, the process area is wetted with disinfectant (e.g. hydrogen peroxide, sodium hydroxide, etc.) via the CIP system.

Optional flooding of the process area

The centrifuge can be flooded with CIP liquid to just below the cover. This process permits contact between the cleaning liquid and the soiled surfaces as long as required and therefore maximum effect.

GMP design for efficient cleaning

Our designs comply with the latest GMP guidelines. The hygenic cleaning of the process area is made possible by a clean finish, excellent surface quality, compliance with minimum radii and the use of FDA-approved open O-rings.

Low solvent consumption

The compact design as well as optimised cleaning programs ensure efficient cleaning with low solvent consumption.

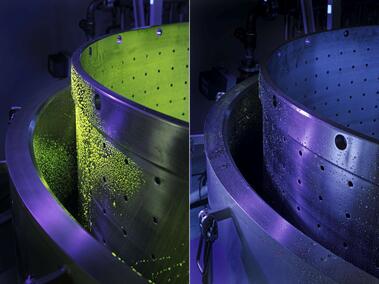

Riboflavin tests

Verifiable cleanliness

We optimise the CIP programs for the different centrifuge types with the aid of riboflavin tests. This way it is ensured that even with low solvent consumption, all surfaces in the process area are wetted with cleaning liquid. Riboflavin tests will be demonstrated on request during the FAT (Factory Acceptance Test).

Brochures

Download matching brochures for the product as PDF here.

Your contact person

Find the right contact person for your needs at Ferrum, our agencies and locations.

We look forward to hearing from you.