Pre-assembled Rotor for your Overhaul

Keep Production Running with ferruLoop

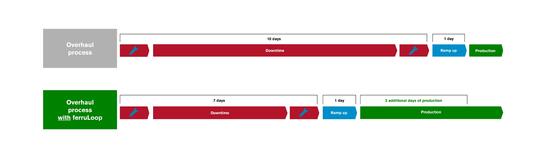

Downtime is costly. Every hour your seamer is out of operation means lost production, missed deadlines, and frustrated customers. Traditional overhauls take time — and in the rare case of a breakdown, the impact can ripple through your entire schedule.

ferruLoop changes that. With our innovative system, you can replace worn or damaged components instantly using pre-assembled rotor upper and lifting station units. This means your production can be back up and running in a fraction of the usual time.

To ensure everything runs smoothly, a Ferrum service technician supports you on-site during the first days of operation — guaranteeing a seamless restart and peak performance from day one.

ferruLoop: less downtime, more productivity, and complete peace of mind.

How it works

Your advantages

- Reduction of downtime: Save up to 3 days during the annual overhaul of your ferruBasic seamer

- Minimize risks: Reduce downtime in case of an unlikely machine breakdown and prevent massive production losses

- Multiple usage: The same rotor can cover more than one seamer of the same type. Lifting stations are compatible between F12 and F18 or from F05 to F08

- Process stability: The replaced units are overhauled in your local workshop after the production start up, while a Ferrum service engineer is present. This ensures production monitoring in case of emergencies

- Optimize planning: More purposeful deployment of your ressources during the annual overhaul

Overhaul process

Components of the offer

You’ll receive the pre-assembled units fully complete and ready for immediate operation.

Contact us

Ready to experience minimal downtime and maximum efficiency? Contact us today to receive your personalized ferruLoop offer.