Development new series of rinsing flaps for pusher centrifuges

06. Feb 2017

New development of the rinsing flaps for your pusher centrifuges

It is generally known, that pusher centrifuges require periodic rinsing. In normal operation crystal deposits can build up inside the centrifuge which can ultimately lead to operating problems. For this reason the centrifuge requires in regular intervals rinsing to dissolve away these crystal deposits. To do this, the Ferrum pusher centrifuges are fitted with several rinsing nozzles, strategically positioned to allow efficient rinsing with minimal rinsing liquid requirements.

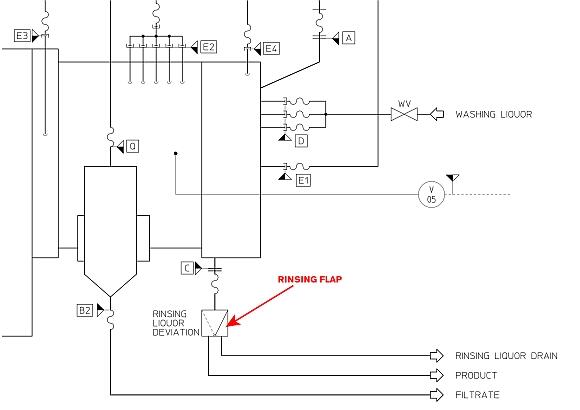

However, it cannot be completely avoided that a part of the rinsing liquid enters the solids discharge area. To prevent this is in an innovative way, Ferrum has developed a new series of rinsing flaps which divert the rinsing liquid reaching the solids discharge area during the rinsing process away to a separate outlet.

The rinsing valves are suitable for all Ferrum pusher centrifuges and available in most materials of construction. The opening and closing function of the flap is manual using a hand lever or automatic using a drive motor. In addition to the rinsing flap, Ferrum can offer a suitable compensator with guide channel to compensate any lateral and axial movement that occurs and any slight misalignment of downstream components.

For further information please contact your responsible partner at Ferrum under Contacts Sales new machines if in connection with a new centrifuge or Contacts Customer service if for a retrofit. We look forward to your call.

Please find more interesting details about “Ferrum Centrifuge Technology” here.