Ferrum Innovation - Integrated thickener

08. Aug 2017

The integrated thickener developed and patented by Ferrum saves space and costs.

Pusher centrifuges require a sufficient solids concentration of the suspension to guarantee safe and constant operation. Furthermore, the pusher centrifuges run smoother and with minimum vibrations if the suspension shows optimum and constant solids concentration.

To ensure such process conditions additional thickening of the suspension upstream of the centrifuge is often necessary. This requires the installation of additional equipment, e.g. static thickener, hydrocyclone or curved sieve, is usually required.

Several years ago, Ferrum developed and patented the integrated thickener which is installed inside the centrifuge as an alternative. Under certain process conditions, the necessity of a separate external thickener is eliminated. This saves space and costs. At the same time, the centrifuge runs more stable and with less vibrations.

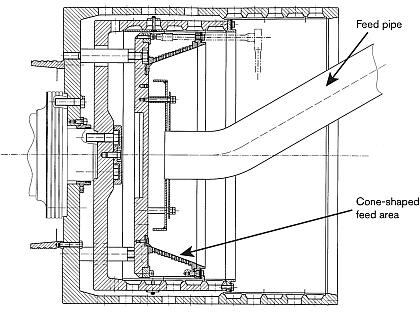

Sketch: Ferrum integrated thickener for pusher centrifuges

The Ferrum integrated thickener is installed in the feed area of the centrifuge and is cone-shaped so that the cake slides independently, by centrifugal force, over the filter surface. Due to thin layer filtration the filter resistance is substantially lower than with cake filtration, i.e. the filtration performance in the feed area is significantly higher than for a standard pusher centrifuge. In this way, the solids content after the thickening cone can be increased and normal cake formation is possible.

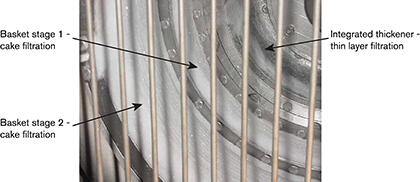

Integrated thickener installed

The integrated thickener has been further developed to allow different, project specifically designed filter media to be applied. There are suitable solutions even for corrosive and/or highly abrasive applications.

Further functions such as classification (deliberate separation of a fine fraction) or an intensive product washing within the feed area are, under certain process conditions, also possible.

Are you interested in further information or product tests? Please contact our

Mr. Philipp Ruhstaller, Head of Process Technology

E-Mail

T +41 62 889 1437

Or send the details of your solid-liquid separation task with our Questionnaire to the Area Sales Manager responsible for your area.

We look forward to your feedback.

For further information regarding 'Ferrum Centrifuge Technology' please click here.