New fill level control + Online monitoring

08. Mai 2017

Ferrum introduces a new Contact-free fill level control and Online monitoring system for scraper centrifuges.

Today the fill level of scraper centrifuges is most commonly monitored using a mechanical overfill protector. This mechanical solution (paddle system) can be used for both vertical and horizontal scraper centrifuges.

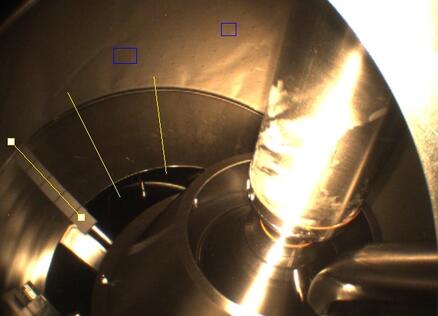

As an alternative, Ferrum now offers an innovative contact-free fill level control system for new and existing scraper centrifuges. Monitoring is based on a camera system which is approved for use in a Zone 1 area, according to ATEX.

The following table shows a comparison of the two systems:

| Paddle | Camera |

|---|---|

| Mechanical system | Optical system |

| Max. fill level switch | Detection of the fill level and identification of the liquid and the solid phase on product surface |

| Simple and robust system | Additional functions possible (Online monitoring) |

| Mechanical contact with the product at the switch-point | No contact with the product |

The camera is mounted on the cover of the centrifuge (flange > DN 100). Ready-to-install hardware and the corresponding Vision software are included in the basic scope of supply. Also available is a black box software module (PLC bases) especially developed by Ferrum, for the control of the camera system and for the communication with the centrifuge control system or with the distributed control system.

Additional functions

The system offers much more. By measuring the intensity it can differentiate between a dry and a fluid surface on the product. With intensity changes the degree of purity of the product can also be monitored, so optimising the wash liquid quantity.

The plausibility of the measured values is verified using special software developed by Ferrum. In this way potential disturbances which may distort the measured values are eliminated.

Using this system, each operating sequence of the centrifuge can be optimised and adapted to fluctuating product characteristics and changing operating conditions. This improves operating efficiency and can increase throughput. As a result, this innovative system has excellent potential as a retrofit on existing centrifuges and will pay for itself in a very short period of time.

Online monitoring

Another important benefit of the camera is the continuous visual access to the inside of the centrifuge allowing monitoring of the centrifuge (Online monitoring) at all times, ensuring additional safety during operation.

For further information please contact your responsible partner at Ferrum under Contacts Sales new machines if in connection with a new centrifuge or Contacts Customer service if for a retrofit. We look forward to providing a quote.

Please find more interesting details about "Ferrum Centrifuge Technology" here.